Stainless steel welded plate heat exchanger

product introduction

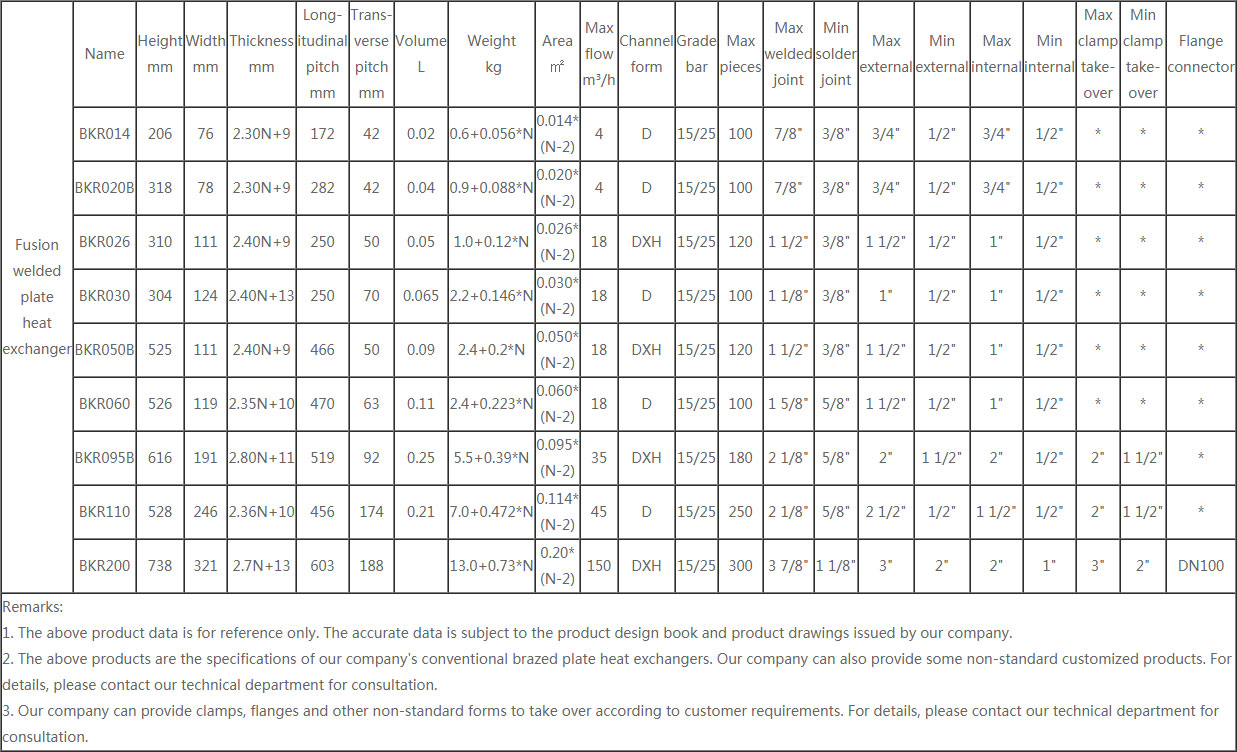

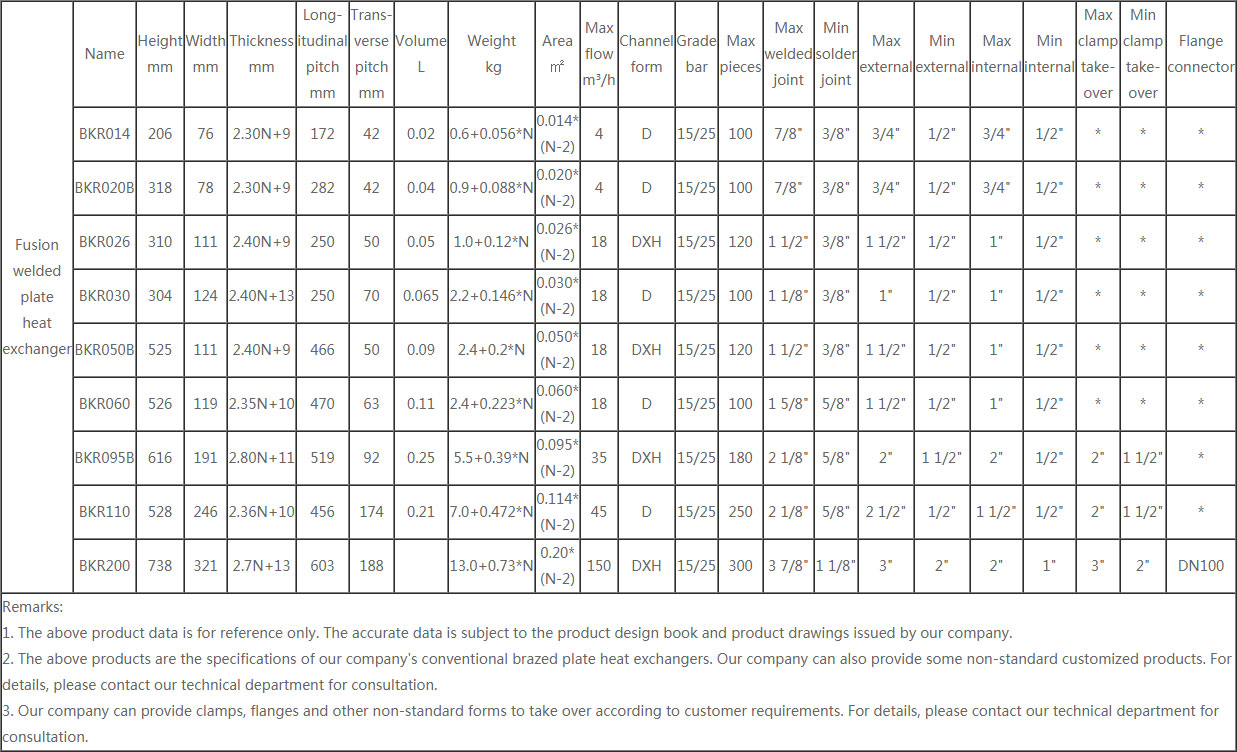

Performance parameters: Temperature: ≤ 550 ° C; Pressure: ≤ 25 bar; Flow: ≤ 200m3 / h

Benefits: Suitable for high cleanliness requirements or for avoiding heat transfer under copper/nickel ion contamination conditions. Corrosion resistant, high temperature resistant, high pressure and other harsh conditions. Health, food grade. Compact structure.

Material: End plate: Stainless steel; Interface: Stainless steel; Plate: Stainless steel; Welding material: Stainless steel

Product Benefits

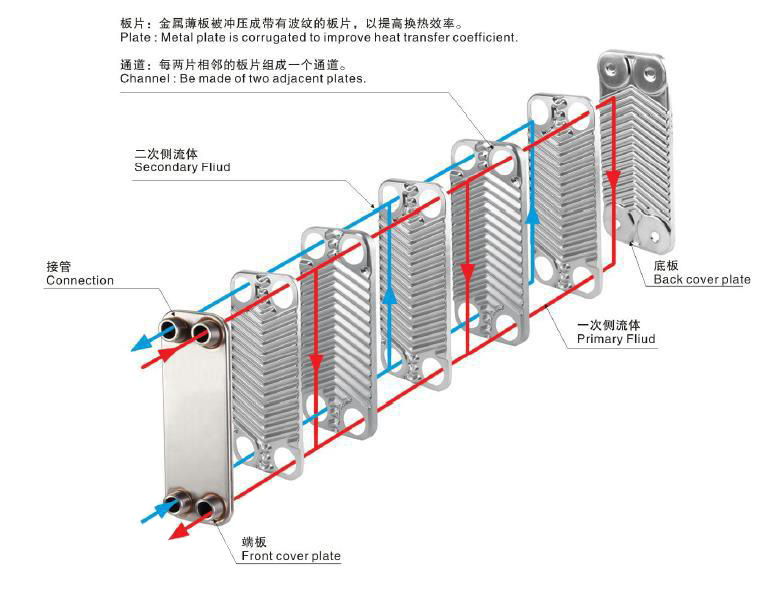

The hygienic and corrosion resistance of all stainless steel welded plate heat exchangers is unmatched by any other brazed plate heat exchanger. Under some temperature changes and pressure fatigue conditions, the traditional brazed heat exchanger is not competent, and the use of high-efficiency plate heat exchangers becomes feasible under these conditions due to the appearance of all-stainless steel welded plate heat exchangers.

All stainless steel welded plate heat exchangers break through the limitations of heat exchangers for gaskets and brazing, when industrially handling high temperature, corrosive media, The stainless steel welded plate heat exchanger provides a plate heat exchanger solution with high efficiency heat transfer, good sealing and low operating cost. The stainless steel construction allows it to withstand temperatures up to 550°C.

In order to ensure high safety, reliability and durability, all stainless steel welded plate heat exchangers have been thoroughly tested, focusing on pressure fatigue, temperature fatigue And corrosion resistance. This reliability, along with innovative design with multiple benefits, makes the all-stainless steel welded plate heat exchanger cost-effective in special industrial heat transfer solutions. For example, the ammonia refrigerant system's corrosion resistance makes it possible to apply a large number of all-stainless steel welded plate heat exchangers to heating devices with corrosive media.

Food-grade heat exchange channels and high mechanical strength make all-stainless steel welded plate heat exchangers an industry choice for hygienic conditions, such as clean water chillers, Tap water heating system, etc.

Product Specification Data Sheet