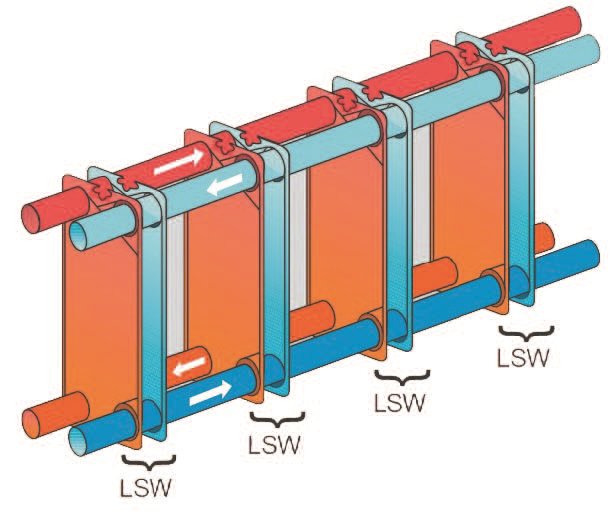

Detachable plate heat exchanger

| Jiangsu Bink BKW Series Laser Semi-welded Plate Heat Exchanger Product Specification Data Sheet | ||||||||||||

| 16Bar | 25Bar | Standard take-up caliber | Effective heat exchange area of the veneer | Number of assembled plates | Max flow | Plate thickness | Product height | Product width | Plate height | Plate width | Corner hole spacing | Clamping size |

| m³/h | mm | mm | mm | mm | mm | mm | mm | |||||

| BKW050-NAXXX | BKW050-NBXXX | DN50 | 0.12㎡ | 240 | 36 | 0.6/0.7 | 920 | 320 | 747 | 248 | 640*140 | N*(3.0+X) |

| BKW100-NAXXX | BKW100-NBXXX | DN00 | 0.24㎡ | 510 | 145 | 0.6/0.7 | 1084 | 470 | 871 | 371 | 719*225 | N*(2.5+X) |

| BKW150-NAXXX | BKW150-NBXXX | DN150 | 0.46㎡ | 470 | 320 | 0.6/0.7 | 1815/1940 | 610/650 | 1498 | 498 | 1294*298 | N*(2.5+X) |

|

Remarks: 1. The above product data is for reference only. The accurate product data is subject to the product design book and product drawings issued by our company. 2. The letter "N" in the product model column indicates the number of undetermined plates; the letter "XXX" indicates undetermined product assembly information. |

||||||||||||